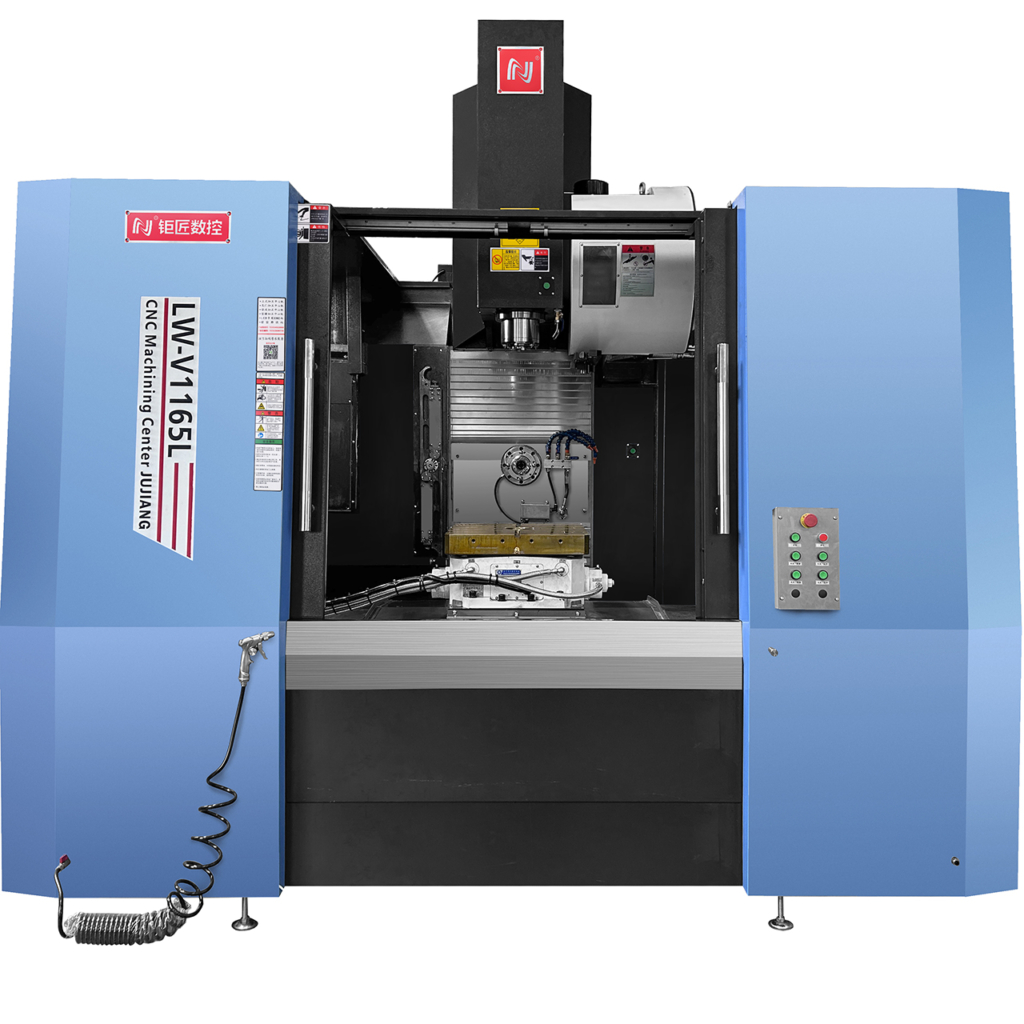

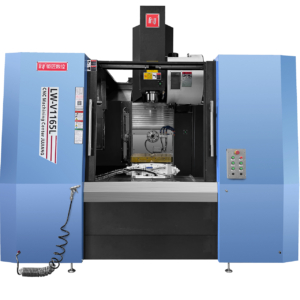

LWV1165L (Fanuc 5-pack system + direct-connected BT40 spindle + direct-connected BT40 spindle + knife-arm 24T vertical tool magazine + knife-arm type 24T horizontal tool changer) technical parameters

| serial number | Machine name:Vertical and horizontal machining center | Product modelLWV1165L | quantity | Remarks |

| One、Primary configuration | ||||

| 1 | Body material | HT300 body | 1platform | Craftsman |

| 2 | Sheet metal type | Full hood sheet metal | 1cover | Craftsman |

| 3 | Control system | Fanuc 5-pack control system | 1cover | Fanucco |

| 4 | X/Y/Z1/Z2 shaft screw | X/Y/Z1/Z2:4012/4012/4012/4012Precision grade lead screw | 4strip | Shangyin/Yintai |

| 5 | Three-axis rail | X/Y/Z:RG45/RG45/RG45 precision grade rails | 6strip | Shangyin/Yintai |

| 6 | X/Y/Z1/Z2 axis servo and drive | Fanuc XYZ1Z2:biS22-3000/biS22-3000/

biS22B-3000 /biSc22B-2000 |

4cover | Fanucco |

| 7 | spindle | crouch:BT40—φ140—12000rpm | 1strip | Taiwan DEJo/Rui Ying |

| 8 | stand:BT40—φ150—12000rpm | 1strip | Taiwan DEJo/Rui Ying | |

| 9 | Spindle drives and motors | crouch:biI8/12000—B SP | 1cover | Fanucco |

| 10 | stand:biI8/12000—B SP | 1cover | Fanucco | |

| 11 | Lead screw bearings | 30TAC/30TAC/30TAC matched bearings | 8Right | FAG/NSK/NACHI |

| 12 | Tool changer | Vertical tool changer:24T knife arm type | 1piece | Tokusho / Okada / Furuta |

| 13 | Horizontal tool changer:24T knife arm type | 1piece | Tokusho / Okada / Furuta | |

| 14 | Chip conveyor | Double screw cutting machine | 1cover | Craftsman |

| 15 | Turntable | HCT470 hydraulic four equal 500X500 rotary table | 1cover | Tanzhou |

| 16 | Hydraulic station | 1cover | Jia Huan | |

| Two、Included attachments and technical documents (description:Accessories are required) | ||||

| 1 | Power cord | 4× 10mm² cable | 5rice | |

| 2 | SD card、card reader | 1 each | ||

| 3 | toolbox | 1piece | Does not contain content | |

| 4 | Packing slip | 1portion | ||

| 5 | Certificate of Conformity | 1portion | ||

| 6 | System Instruction Manual (Electronic Files) | 1portion | ||

| 7 | Programming manual (electronic file) | 1portion | ||

| 8 | Installation commissioning test acquirer | 1portion | ||

| 9 | Daily maintenance and precautions of machine tools | 1portion | ||

| Three、Customer optional configuration | ||||

| Model | model | Unit | |

| Itinerary Travel | |||

| X-axis travel(The turntable moves left and right) | X-axis travel | mm | 1100 |

| Y1 axis travel(The saddle moves back and forth) | Y1-axis travel | mm | 700 |

| Y2 axis travel(The horizontal headstock is moved up and down) | Y2-axis travel | mm | 500 |

| Z1 axis travel (vertical headstock up and down) | Z1-axis travel | mm | 540 |

| Z2 axis travel (saddle moving back and forth) | Z2-axis travel | mm | 700 |

| Vertical spindle center to horizontal spindle end face | Distance from vertical spindle center to horizontal spindle end face | mm | 655 |

| Distance from vertical spindle end face to work table | Distance from vertical spindle end face to workbench surface | mm | 150-690 |

| Horizontal spindle centerline to table surface distance | Distance from horizontal spindle centerline toworkbench surface | mm | 50-550 |

| The distance from the horizontal spindle end face to the center line of the table | Distance from the end face of the horizontal spindle to the centerline of the workbench | mm | 305-1005 |

| Vertical spindle centerline to column rail distance | Distance from spindle center to column rail | mm | 797 |

| Workbench Worktable | |||

| Table size | Worktable size | mm | 500×500 |

| Maximum load bearing capacity of the table | Worktable maximum load | kg | 700 |

| T-slot | Worktable T-slot | mm | 5-18-100 |

| Minimum set angle | Minimum setting angle | Deg. | 90° |

| Cumulative segmentation accuracy | Accumulated segmentation accuracy | Sec. | 4″ |

| Repeatability | Repeatability | Sec. | ±1″ |

| Maximum swing diameter | Maximum turning diameter | mm | 1210 |

| Spindle Spindle | |||

| Spindle speed(Vertical/horizontal) | Spindle Speed | .rpm | 12000/12000 |

| Spindle power(Vertical/horizontal) | Spindle motor power | KW | 7.5/7.5 |

| Spindle taper hole(Vertical/horizontal) | Spindle taper hole | BT40-φ150/

BT40-φ140 |

|

| Spindle spring chuck(Vertical/horizontal) | Spindle collet chuck | C32/C32 | |

| Loose knife way(Vertical/horizontal) | Unlock tool way | Pneumatic booster cylinder knife / pneumatic booster cylinder knife | |

| Clamp armTool magazine | |||

| Vertical tool changer capacity | Tool magazine Capacity | T | 24 |

| Horizontal tool magazine capacity | Tool magazine Capacity | T | 24 |

| Federate | |||

| X/Y/Z1/Z2 axis express displacement | Ted X/Y/Z1/Z2 axis express displacement | mm/min | 36000 |

| Cutting feed rate | Cutting feed rate | mm/min | 12000 |

| Accuracy | |||

| Positioning accuracy | Pointing accuracy | mm | ±0.003/300 |

| Repeatable positioning accuracy | Repeat ability accuracy | mm | ±0.002/300 |

| Machine information | |||

| Machine tool dimensions | Machine dimension (L×W×H) | mm | 3300*3300*2800 |

| Machine weight

|

Machine weight | kg | 7000 |

| Power demand (power/current) | Power requirement | KVA | 25 |

Jutuo Intelligence

Jutuo Intelligence