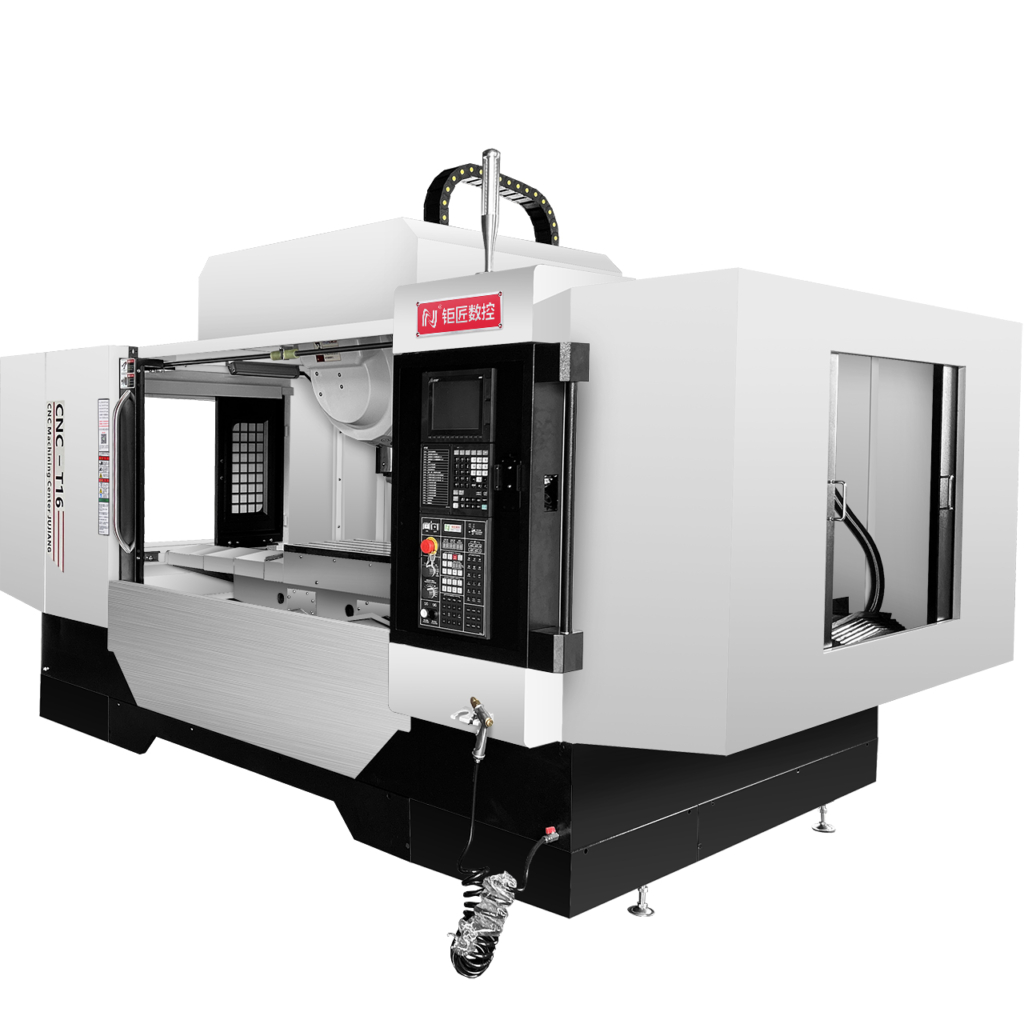

CNC-T16 (Mitsubishi M80B system + direct-coupled BT30 spindle)Technical parameters

| Model |

model |

Unit) |

|

| Itinerary Travel |

| X-axis travel |

X-axis travel |

mm |

1600 |

| Y-axis travel |

Y-axis travel |

mm |

540 |

| Z-axis travel |

Z-axis travel |

mm |

320 |

| Distance from spindle end face to work table |

Distance from guide plane to spindle center |

mm |

140-440 |

| The distance from the spindle centerline to the column guideway |

|

mm |

585 |

| Workbench Worktable |

| Table size |

Worktable size (L×W) |

mm |

1700×500 |

| Maximum load-bearing |

Maximum load |

kg |

650 |

| T-slot |

T-slot |

mm |

5-14-100 |

| Spindle Spindle |

| Spindle speed |

Spindle Speed |

.rpm |

20000 |

| Spindle power |

Spindle motor power |

KW |

5.5 |

| Spindle taper hole |

Spindle taper hole |

|

BT30-φ95 |

| Spindle spring chuck |

Spindle collet chuck |

|

ER25 |

| Loose knife way |

Unlock tool way |

|

Mechanical |

| Tool magazine |

| Tool magazine capacity |

Tool magazine Capacity |

T |

21 |

| Maximum tool length |

Max tool length |

mm |

150 |

| Maximum tool diameter/empty knife |

Maximum tool diameter |

mm |

60/80 |

| Maximum tool weight |

Maximum tool weight |

Kg |

3 |

| Tool change time |

Tool change time |

Sec |

0.3~1.2 |

| Federate |

| X/Y/Z express displacement |

Ted X/Y/Z axis express displacement |

mm/min |

X:30000/YZ:480000 |

| Cutting feed rate |

Cutting feed rate |

mm/min |

12000 |

| Accuracy |

| Positioning accuracy |

Pointing accuracy |

mm |

±0.005/300 |

| Repeatable positioning accuracy |

Repeat ability accuracy |

mm |

±0.003/300 |

| Machine information |

| Machine tool dimensions |

Machine dimension (L×W×H) |

mm |

4200×2660×2300 |

| Machine weight

|

Machine weight |

kg |

5000 |

| Power demand (power/current) |

Power requirement |

KVA |

15 |

1.Aluminum profile - air conditioner home appliance aluminum alloy shell、LED TV frame、Aluminum alloy functional furniture tracks, etc

2.Automation equipment robot - automatic loading and unloading track、The robot moves the track、Functional structural parts, etc

3.Aerospace - aluminum-magnesium alloy fuselage structural parts、Precision machining such as luggage racks

4、New energy vehicle - aluminum alloy body skeleton、Battery chassis tow、Battery compartment cover、Sunroof rails,luggage rack、Precision machining such as bumpers

CNC-T16 (Mitsubishi M80B system + direct-coupled BT30 spindle) model optional configuration (charged)

| serial number |

Accessory name |

Product model |

quantity |

Remarks |

| 1 |

̈Optional five-shaft (turboworm) |

The main body FAR125 motor + drive |

1cover |

|

| 2 |

̈ Optional five-shaft (harmonic gear) |

Body J160 motor + drive |

1cover |

|

| 3 |

̈ Optional four-axis (body) |

Ontology AR170,Drive + motor |

1cover |

|

| 4 |

̈ Optional four-axis (body + disc tailstock) |

Ontology AR170,Drive + motor,Disc tailstock RTA170,Block L,Bridge plate |

1cover |

|

| 5 |

̈ Optional four-axle (body + top tailstock) |

Ontology AR170,Drive + motor,TJ170 top tailstock,Chuck flange |

1cover |

|

| 6 |

̈ Flat nose pliers should be optional |

6inch |

1piece |

|

| 7 |

̈ An optional refractometer is required |

Handheld 0-60 |

1cover |

|

| 8 |

̈Precision cutting head is optional |

BT30-ER25-70mm (with card slot) |

1piece |

|

| 9 |

̈ Optional locking tool holder |

BT30 with card slot lock tool holder |

1piece |

|

| 10 |

̈ Optional lock knife wrench |

ER25 locker wrench |

1handful |

|

| 11 |

̈ Precision spring clip is optional |

ER25 3/4/6/8/10/12 |

1 each |

|

| 12 |

̈ To choose a U disk |

|

1piece |

|

| 13 |

̈ To choose a combination pressure plate |

M12 combination platen |

1cover |

|

Jutuo Intelligence

Jutuo Intelligence