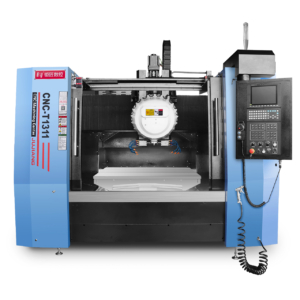

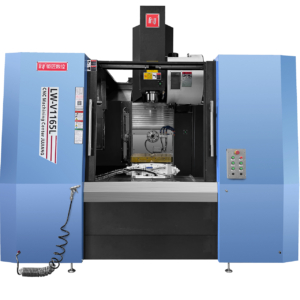

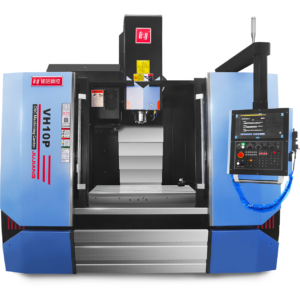

| Model | model | Unit | |

| Itinerary Travel | |||

| X-axis travel | X-axis travel | mm | 800 |

| Y-axis travel | Y-axis travel | mm | 585 |

| Z-axis travel | Z-axis travel | mm | 600 |

| Distance from spindle end face to work table | Distance from guide plane to spindle center | mm | 200-800 |

| The distance from the spindle centerline to the column guideway | Distance from spindle center to column rail | mm | 672 |

| The maximum diameter of rotation of the workpiece when the turntable is upright | Max workpiece rotation diameter | mm | Φ820 |

| Workpieces can be machined(Length X Width X Height)

(Clamp included) |

Machinable workpiece size

(length*Width*Height)(Including fixtures)

90 |

mm | 650X512X140 |

| Workbench Worktable | |||

| Five-axis table size | Worktable size | mm | Φ350 |

| Maximum load-bearing | Maximum load | kg | 300 |

| T-slot | T-slot | mm | 4-12-90° |

| Spindle Spindle | |||

| Spindle speed | Spindle Speed | .rpm | 12000 |

| Spindle power | Spindle motor power | KW | 7.5 |

| Spindle taper hole | Spindle taper hole | ER25 | |

| Loose knife way | Unlock tool way | Mechanical | |

| Clamp armTool magazine | |||

| Tool magazine capacity | Tool magazine Capacity | T | 21 |

| Maximum tool length | Max tool length | mm | 150 |

| Maximum tool diameter/empty knife | Maximum tool diameter | mm | 60/80 |

| Maximum tool weight | Maximum tool weight | Kg | 3 |

| Tool change time | Tool change time | Sec | 0.3~1.2 |

| Federate | |||

| X/Y/Z express displacement | Ted X/Y/Z axis express displacement | mm/min | 48000 |

| Cutting feed rate | Cutting feed rate | mm/min | 12000 |

| Accuracy | |||

| Positioning accuracy | Pointing accuracy | mm | ±0.003/300 |

| Repeatable positioning accuracy | Repeat ability accuracy | mm | ±0.002/300 |

| Machine information | |||

| Machine tool dimensions | Machine dimension (L×W×H) | mm | 2800*2800*2900 |

| Machine weight

|

Machine weight | kg | 5000 |

| Power demand (power/current) | Power requirement | KVA | 15 |

Jutuo Intelligence

Jutuo Intelligence