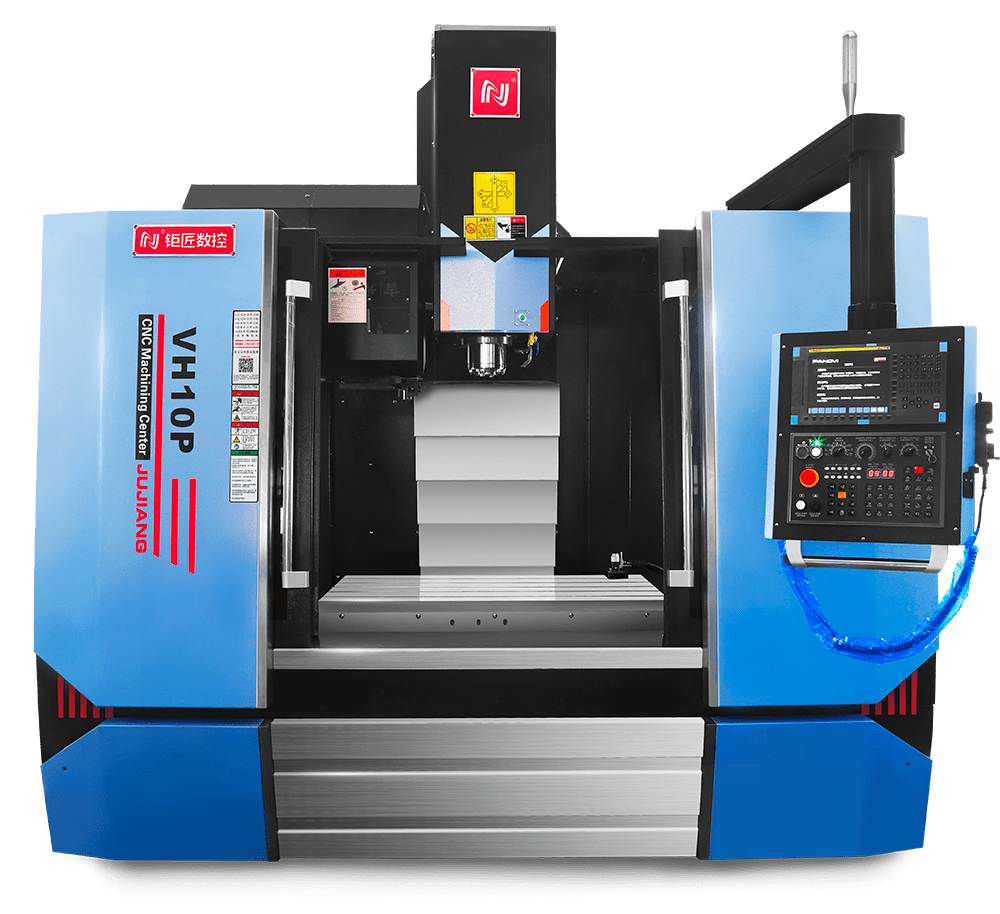

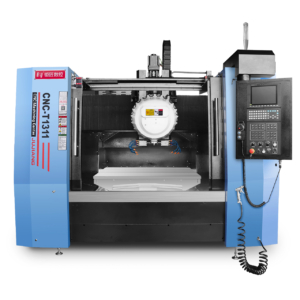

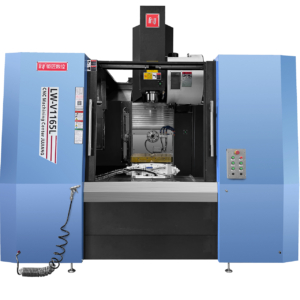

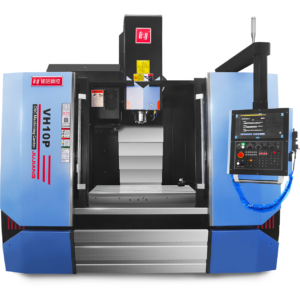

1、Y-axis four-rail eight-slider、Extra-wide base,The support is rigid;

2、Double spiral + chain plate chip conveyor,Easy chip evacuation,Significant savings in time and labor costs。

3、The saddle is fully supported,No overhang,The accuracy is super stable;

4、Extra-wide column design,Large mating surface connection,The structure is rigid;

5、Equipped with a nitrogen balance system,The Z-axis runs more smoothly,Guaranteed running accuracy。

6、BT40-24T cutter arm type tool magazine is adopted,The tool change speed is 2.3 seconds,High processing efficiency;

7、It adopts high-rigidity P-class roller precision linear guide

8、High-precision C3 ball screw is used。

9、High rigidity is adopted、High-precision BT40-150 direct-coupled spindle,High cutting force,High precision。

10、Japan FANUC is adopted、Japan MITSUBISHI high-performance CNC system,Paired with high responsiveness、High precision、High torque、Low-noise servo motor。

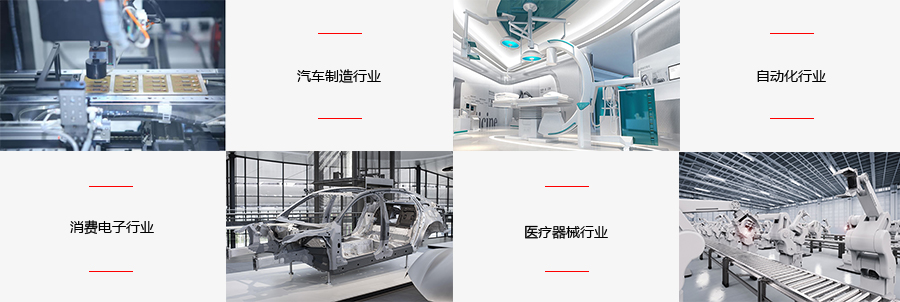

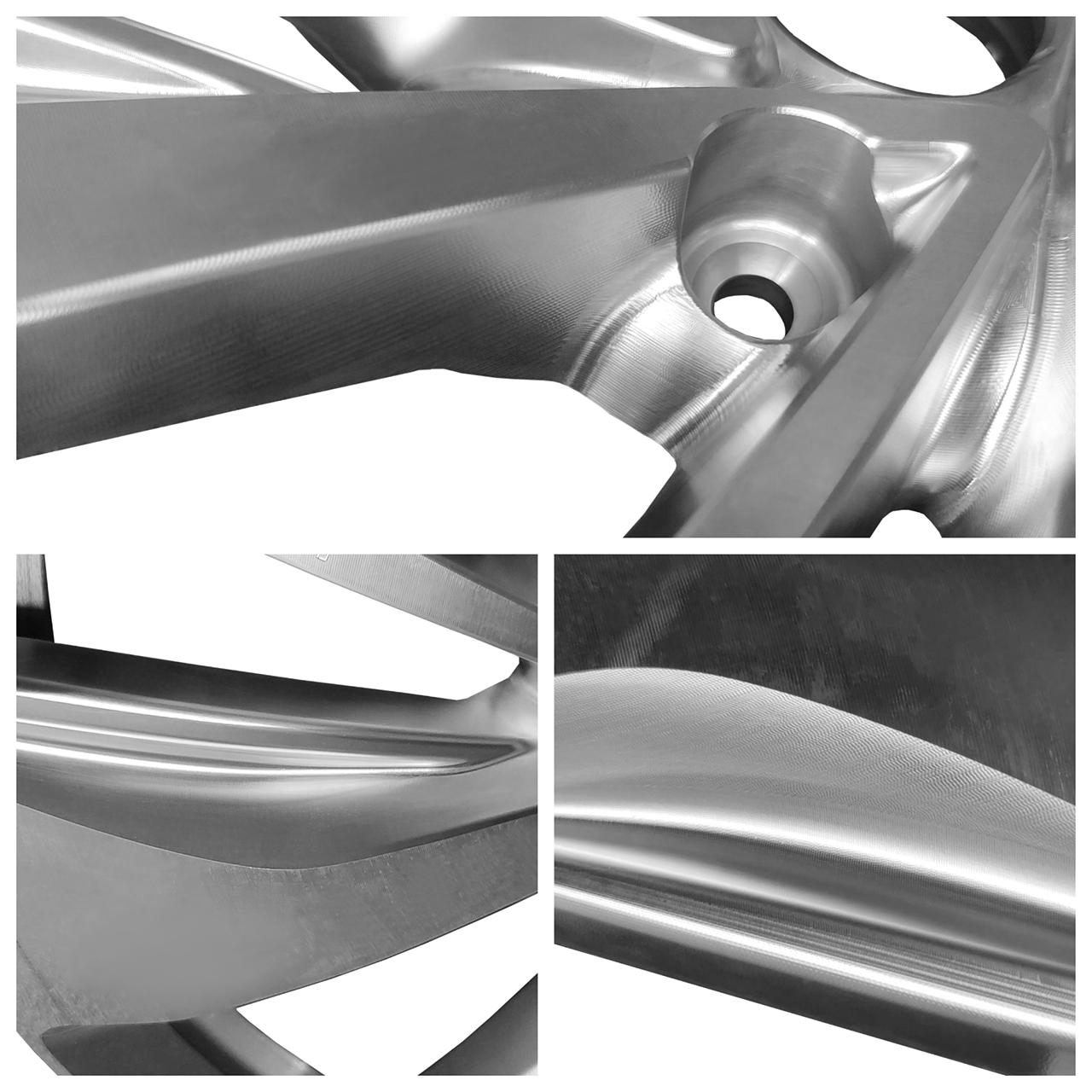

11、Developed for forged automotive wheels、It is fully suitable for forging automobile wheel hub machining,It perfectly solves a variety of processing processes for forging automobile wheels,Compared with the traditional machining center, the processing efficiency is increased by more than 30%.。

VH10P (Fanuc 3 Bags + Direct Coupled BT40 Spindle + Arm 24T Tool Magazine)Technical parameters

Technical Parameters

| Model | model | Unit) | |

| itineraryTravel | |||

| X-axis travel | X-axis travel | mm | 1000 |

| Y-axis travel | Y-axis travel | mm | 700 |

| Z-axis travel | Z-axis travel | mm | 700 |

| Distance from spindle end face to work table | Distance from guide plane to spindle center | mm | 110-810 |

| The distance from the spindle centerline to the column guideway | Distance from spindle center to column rail | mm | 777 |

| workbenchWorktable | |||

| Table size | Worktable size (L×W) | mm | 1200×700 |

| Maximum load-bearing | Maximum load | kg | 1000 |

| T-slot | T-slot | mm | 5-18-125 |

| spindleSpindle | |||

| Spindle speed | Spindle Speed | .rpm | 15000 |

| Spindle power | Spindle motor power | KW | 11 |

| Spindle taper hole | Spindle taper hole | BT40-φ150 | |

| Spindle spring chuck | Spindle collet chuck | C32 | |

| Loose knife way | Unlock tool way | Pneumatic booster cylinder knife | |

| Knife arm type tool magazineTool magazine | |||

| Tool magazine capacity | Tool magazine Capacity | T | 24 |

| Feed rateFederate | |||

| X/Y/Z express displacement | Ted X/Y/Z axis express displacement | mm/min | 30000/30000/30000 |

| Cutting feed rate | Cutting feed rate | mm/min | 15000 |

| precisionAccuracy | |||

| Positioning accuracy | Pointing accuracy | mm | ±0.003/300 |

| Repeatable positioning accuracy | Repeat ability accuracy | mm | ±0.002/300 |

| Machine informationMachine information | |||

| Machine tool dimensions | Machine dimension (L×W×H) | mm | 3100*3200*3200 |

| Machine weight

|

Machine weight | kg | 8800 |

| Power demand (power/current) | Power requirement | KVA | 35 |

※As the company is constantly improving its products,Therefore, the company reserves the right to change the design and specifications and configuration at any time without notice,

If patronized,Please check if the specifications have changed!

Jutuo Intelligence

Jutuo Intelligence